H-brace Prep and Install

H-brace Prep and Paint

Each Spar and Boom tube will receive a steel brace in the middle to spread the flight loads imposed by bolting other structures to them. This is a very important feature of the Kolbs. Other, competing designs didn't have this additional structure.

Each H-brace was powder coated on the outside, but had no corrosion prevention on the inside. Steel rusts very quickly if left unpainted. How do you clean the insides of the braces and apply paint? I located bronze brushes used to clean shotgun barrels, of the correct size, and using MEK, scrubbed the inside of the tubes using the shotgun cleaning kit.

The process removed a surprising amount of rust from the insides of the tubes. That cleaning patch was white just a moment before.

Kept scrubbing with the bronze brush, then running a clean patch dipped in MEK through until the patch came out clean.

Finished product: the insides of the tubes were evenly coated with the epoxy paint. No chance of rust developing in the years ahead.

H-brace Install

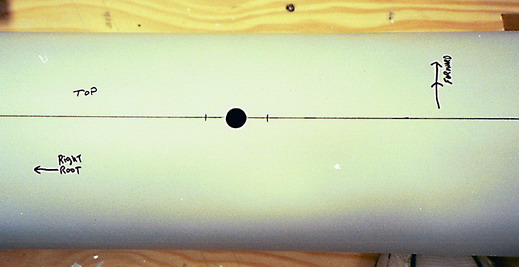

Each H-brace had to be slid into the spar, then riveted into the exact centerline. That required locating the centerline of the spar, marking with a pen, and drilling a row of holes. If misdrilled, the entire spar must be replaced. Feeling the presure? First drill the hole for the lift strut bolt, then drill the holes for the rivets on the centerline.

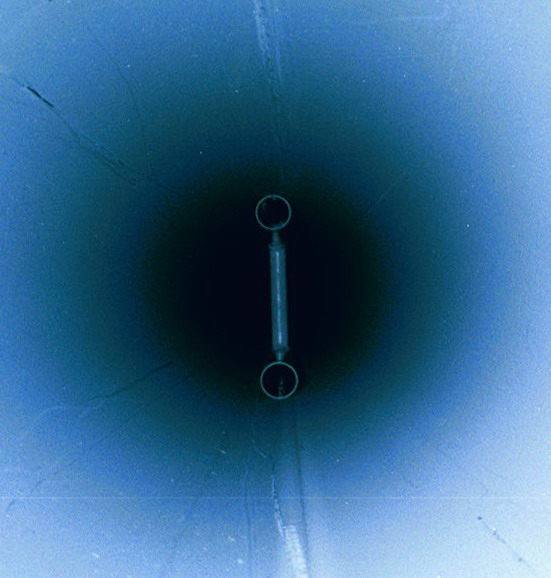

Slid the H-brace into position with long 2x4's used like chop sticks. Only a few scars in the paint. Toward the end of the wing build, more paint can be sloshed inside to ensure coverage. This photo gives the illusion the brace isn't centered, in fact it is exactly centered.

Drill through the holes to the H-brace, and slowly drill into the steel. I placed a line with a sharpie on the apex of the H-brace before install, then looked for the line inside the holes to verify the H-brace was in fact on the centerline of the tube. Started with the #40 drill, then cleco, and went back and drilled out to #30 and clecoed. Steel parts give the cleanest hole by starting with a small hole then drilling larger.

Lots of holes.