Wings

I had much prep work to finish before the parts of the wing were ready to be assembled. Several Kolb builders have come up with various improvements over the years, and I spent months considering them, and reviewing them with local A&P friends (aircraft mechanics), and members of the Kolk e-mail list I belong to. Out of those conversations, I selected the improvements I liked as well as several of my own improvements. Every time I changed the design, I spent much time planning and considering, as well as getting unanimous agreement from my advisors before making any change. The final choices were up to me, so I alone am responsible for the outcome of this project.

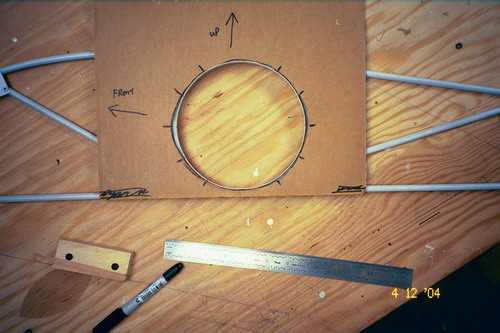

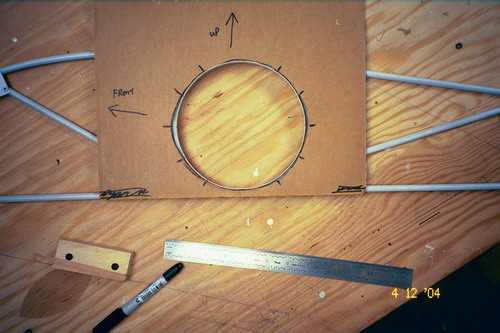

Marking the rib flanges for rivets with my custom tool :-)

Made a perfectly level jig by planing flat 2x4's and shiming them to the table. Placed the spar tube on the table and slid the ribs onto the tube. The paint made the process scratch free since the aluminum was protected. Cut and placed the leading edge tube, then the trailing edge tube.

Another view of the same thing. At first the jig held the wing in two places, with the end of the wing hanging.

Wing modifications

Used tiedown straps to pull the leading and trailing ends of the wing together while I shimmed and adjusted the wing to make it perfectly straight. This was the first time all the parts began to look wing-like. Note the extra ribs: after much debate, I settled on 5 more ribs than the plans called for, giving a total of 14 ribs per wing. The ribs weight 7.3 ounces each, adding 2.3 pounds per wing. I felt the large increase in strength was worth the 2.3 pounds invested. This reduced rib spacing from 15 inches to 10 inches, thereby significantly increasing the load bearing ability. I chose these and other improvements to the wings because while these planes have an excellent safety record, any design can be improved to optimize a plane for its intended mission. Several folks who have built their Kolb's to travel cross country, through the wilderness have made similar changes. This is the type of flying I want to do.

Also, in the early days of Kolbs, a small group of the builders liked to preform extreme, unapproved, aerobatic maneuvers (you know who you are ;-) and from that there is good data on what the airframe will do if stressed beyond it's limits. I don't make a habit of overstressing airframes, but my flight experience has taught me that wind, bad weather, and other unexpected factors during cross-country flights can place far more stress on the airframe than predicted. Several builders have taken me to task for modifications they think are unnecessary, and will reduce the amount of weight I can carry. They are of course correct. Every pound I add to the plane is one less I can carry. Each builder must find their comfort level between stronger-heavier, and lighter-carries more. After listening carefully and debating the merits of these options for months, I gradually came up with a series of modifications to the airframe that suit me, and my advisors. Many came from the open community of Kolb builders who all offer what they have learned, some from the my local advisors, and a few from the moldy recesses of my head.

Here's a shot of the end of the wing hanging off the jig.

The leading and trailing tubes proved to be more flexible than I expected, so I added another flat, leveled 2x4 to keep the wing in alignment. The yellow string and vise grips are for rough aligning of the jig. The wing is stabilized on the jig with long zip-ties.

Here are 3/4 and 1/2 inch angle aluminum pieces added to increase the strength of the nose area of the wing. The stiffness added by these angles was very impressive and only added 3.5 oz. per rib. I didn't come up with this change, but was very impressed with the strength improvement it offered.

To provide the lateral stiffness these wings need, I placed six 1/2 inch angles as shown. This ties the ribs together, as well as providing far more strength than the 1/2 inch tubing called for in the plans. At 2.4 oz. per piece, and no holes drilled into the spar as the 1/2 inch tubing would have required, this is a good trade-off between strength and additional weight.

Here is another view of the first angle brace I placed on the wing.

At each end of the wing, I added an additional angle brace to the lower side of the wing weighing 2.2 oz.. This assures wing leading edge will never be able to twist out of collumn (the root cause of the aerobatic induced failures).

Total Weight Increase

All the modifications made to the wing (including some not yet shown) increased the wing weight by 9.8 pounds making a total of 19.6 pounds for both wings. I am very satisfied with this and feel the plane can manage the extra 20 pounds and still give the useful load needed to carry two people, a couple hours of fuel and some luggage.